Page Content:

- What is 3D printing?

- 15 USEFUL Prints for cameramen

- D-Tap Voltmeter

- Sunhood

- Follow Focus Gears

- V-Lock battery plate for 30mm rod

- Screen protectors

- Universal Push On lens cover

- DJI Ronin SC2 Cable Clips

- Controller Protector

- PL Mount conversion adapters

- AA Battery Storage Box

- Hidden holder for Rode smartLav

- Board Marker Holder

- 15mm Rod Cable Clip

- Hollyland Mars 400s clip

- Motorized Mini Camera Jib

- In Conclusion

Recently I’ve been enjoying exploring the world of 3D printing. Obviously not a new phenomenon to many, for me I found it be to be an excellent combination between design, creativity and problem solving. And also another sink to put money into! Whilst there are many pointless things out there that are often publicised that can be 3D printed, I wanted to publish an article on useful things for cameramen (and women) to print.

What is 3D printing?

Firstly, let’s just recap what 3D printing is. Fundamentally 3D printing is taking plastic filament and melting it via an extruder on to a heated plate and up across a 3D plane. As the filament is pushed through a nozzle, motors move the nozzle around the build plate whilst a thin strand comes out. Layer by layer an object is created.

There are many hoops you have to jump through however… including setting the printer up (it’s a lot harder than you’d imagine!), creating any supports for over hanging layers that don’t touch the build plate, selecting the correct temperature for your prints, choosing the correct materials for the job and choosing the infill for the object you’re creating. The material you choose will depend on what properties you’re after (hard wearing, flexible, rigid, quick to print…). The material you use will affect the temperature you print at. The infill will basically affect the rigidity of your object but will take longer to print and use more material.

In terms of materials I use, I mainly print using PETG (strong, takes a while to print, oil based), PLA (no so strong, fairly quick to print, plant based) and Flexi (soft, flexible, slow and very difficult to print).

The process of printing something goes as follows… acquire/create your design. This could be either by creating it yourself (Autodesk Fusion 360 and TinkerCAD are two programs that you can use for free to get started) or by downloading an existing design (websites like https://www.thingiverse.com or https://www.printables.com/ a good starting place). You then need to slice those designs up into a code of instructions which you feed your 3D printer (Cura is one of the most common pieces of software to do this). Using the software you specify things like material, nozzle size, printer model, whether to generate supports, etc… You then export a Gcode from the software which you either send or load on to your printer. You can then execute those instructions and print said item…

This is a really top line concept of what 3D printing is (and probably half incorrect!), but I’d suggest having a quick look at the videos below if this is something you wish to know more about…

The Ultimate Beginner's Guide to 3D Printing

OK, so on to some useful 3D printing camera things…

15 USEFUL 3D prints for cameramen

This is a voltmeter which attaches to the side of your camera and is powered off the DTAP connector to tell you what voltage your battery is currently running at. This is really useful for cameramen using the Sony FX6 or Sony FX9 as the cameras as default, have no way of telling you how much voltage you have left in the batteries, if you’re running of V-lock batteries. Something myself and many other users find absolutely infuriating!

Sunhood & SSD holder for ATOMOS Ninja V(& Shinobi)-5" monitor

Sun hoods are really handy on external monitors when shooting outside in bright sunlight. They shade the screen to allow you to see the brightness clearly. This design for the Atomos Ninja/Shinobi is a great add on, reasonable easy/quick to print and something that’s not otherwise available.

These follow focus gears are really handy if you’re shooting with smaller DSLR style lenses and like to work with a follow focus. The problem that I’ve found in the past with the universal follow focus rings, is that as they’re adjustable and have a joining part which often means you have to stop racking when you get to that part. This infinitive design means that you can rack a full 360 degrees without getting caught by the join.

V-Lock battery plate for 30mm rod

This V-Lock battery plate allows you to connect a v-lock battery directly to a 30mm bar. This is great to mount a battery on a Movi, light stand or other gimbal. It’s also something that is often over engineered and quite expensive if buying from a retailer.

Screen protectors for ATOMOS Ninja/Shinobi 5" and 7"

Now these are one of my designs. I was looking for a protector for my monitors whilst in transit to protect the screens from scratching. These are fully flexible, allowing you to bend them and they’ll return to their original form. They are a pain in the neck to print but I felt worth it, due to the cost of repairing scratched screens! I had to modify my Creality Ender 3 printing by adding on the direct drive module. Fairly straightforward and didn’t cost a huge amount to do. However, the material is very temperamental and it’s certainly not just hitting print. It required experimenting with speed, retraction and heat to find the perfect combo. They took a while to print and the material is quite expensive. These models aren’t perfect, but they do the job required and I’m otherwise pleased with them. I’ve also expanded the concept out to protect other things that get knocked together, like electronic modules, etc… although nothing else quite as fully fledged as this yet!

This is quite a cool concept. I’ve designed something similar and printed it in flexi before, however mine didn’t seem to work quite as well as this. I have also tried printing my own fully functioning lens caps too, however the small moving parts in the locking mechanism and the general preciseness of a lens, require very fine printer resolution, which I was unable to achieve. Something slip on like this is much more likely to work!

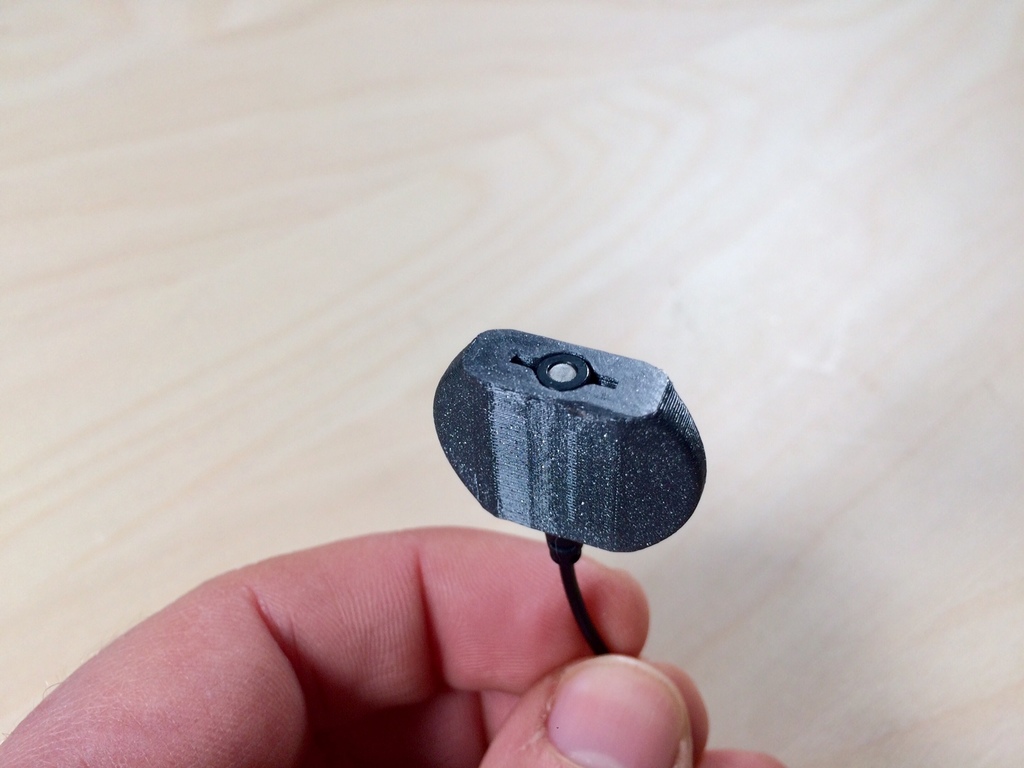

Another one of mine here… I was looking to tidy up the cables between my monitor and my camera on my DJI Ronin SC2. I designed some clips to attach the cables to.

DJI Mavic Controller Protector

Now there’s a ton of designs for DJI drones. Things like screen holders, boxes, cases and GoPro mounts. For me, I was able to print a Quadlock adapter that allows me to use my existing Quadlock phone case to clip into a 3D printed plate which attaches to the remote control. Pretty basic but saves having to take my phone out of the case everytime I use it. That design can be seen here [https://www.thingiverse.com/thing:2089347] but there are a ton of other ones too. However, I’ve gone for something a bit more universal. This seems like a very simple device, but this protector protects your remote control when in transit if you leave the joysticks attached when in your bag. Trust me, I know from experience how easier these controllers break if you leave the sticks on in transit, so this simple device will protect your controller!

PL Mount conversion adapters (PL-E Mount, PL-MFT Mount, PL-EF Mount and front and rear caps)

This is a really cool project. A collection of lens mounts. I’m not sure how well these would actually work in practise due to the strength of the materials, and the fact that lenses need very precise distances to work effectively, but I feel like these definitely have a use at certain times.

This is a great unit that I use regularly to store my AA batteries in whilst in my kit bag. Saves them going everywhere. When dead batteries come out of a microphone, I put them back in the box upside down and remove them when I get back to base. One thing to watch with this one, the catch is quite brittle and not too strong. I ended up printing in PETG at a higher resolution and it’s stayed together very well.

Hidden holder for Rode smartLav

This is based on another well known brand, but is a simple device to hide a microphone under clothing without it rubbing and reducing clothing noise. I’ve tried to design similar things to this in the past, but nothing as well as this. This can be adapted to fit Sennheiser, Sony and Cos-11s.

Board Marker Holder for Cinema Slate

A fairly simple design here, but also really handy if like me, you’re always losing the marker pen for your slate! Keep your pen attached to the back. The added hoop also allows you to hang it off a light stand in between takes.

Pretty basic one here, but I wanted to be able to clip cables to the side of my camera and onto the 15mm rods. This need to be printed in quite high resolution using PETG to remain strong, but pretty much do the job.

Another one from me here… whilst building my directors monitor cage, I was struggling to find a way of securing the receiver for the wireless link to the cage. In the end a built a little clip which would seat the receiver in the cage to stop it constantly falling out. This could easily be adapted to fit other sized receivers.

Now for something a little more out there… a fully motorised mini jib. This is a really cool concept. Very well designed and executed… however I can’t imagine anyone actually building this and can’t imagine it standing up to the stresses and strains of actual work… however seeing something someone has quite clearly put a lot of time and effort into, it’s real inspiration for how 3D printing can help other filmmakers design and build ways of moving their cameras around.

In Conclusion

So there we have 15 useful items every cameraman should print. My journey with 3D printing has really just begun. It’s a really fun experience trying to solve problems in often completely over engineered ways. Fundamentally it’s a lot harder than I initially expected, despite already having experience in the 3D design field. It’s the materials really that are the tricky bit, as nothing really just works out of the box.

There are ideas and designs floating around for products that would revolutionise 3D printing and allow it to be more of a plug and play experience, which would certainly open things up much more widely and you won’t necessarily need a doctorate in material sciences to print a tiny item. However, for now, I’m enjoying the challenge and would certainly encourage anyone else with a mind for engineering to give it go!

Have you got any great 3D printing designs or ideas not mentioned here? Hit me up on Twitter to let me know and I might do an updated blog at another time!